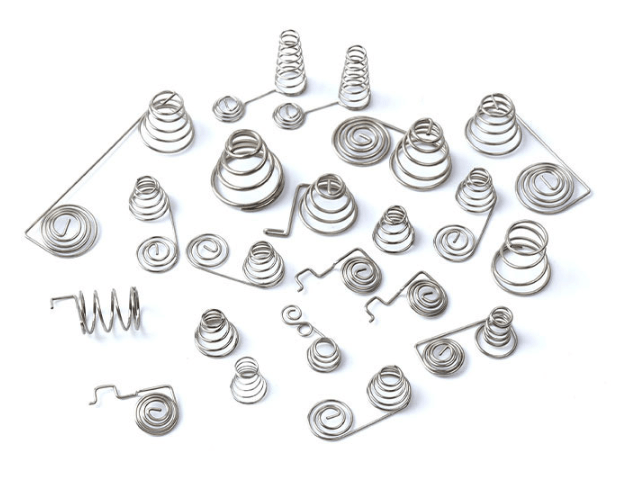

There are different types of springs that frequently play an important function. As a result, each spring has equivalent tight standards in the manufacturing process and must pass a series of strict testing to verify that it meets the standard performance.

1. Spring fatigue performance and relaxation rate detection

These two factors, it may be argued, directly influence the spring's reliability and life, and are the key to the spring's quality. These two indicators can be acquired following specified cycle numbers of load-strain testing utilizing a spring fatigue testing machine.

Spring fatigue testing machine is used for testing.

2. Spring hardness test

Springs, particularly exceptionally big springs, are usually quenched. HRC44 to 52 is the typical hardness range for ordinary springs. And such an aircraft carrier-level spring will outperform HRC52 and possibly even HRC54.

The purpose of evaluating hardness is to evaluate the spring's failure performance.

Testing equipment: hardness tester.

3. Nondestructive testing of springs

Non-destructive testing includes visual inspection. Because of the various production procedures, it is possible that some flaws like as cracks, creases, delaminations, pits, pits, scratches, wire drawings, and other surface defects will occur during the spring's processing. These surface quality flaws are usually detectable through visual inspection or ultrasonic frequency.

Testing equipment: magnifying glass, microscope, ultrasonic detector.

4. Geometric size detection of springs

Size testing components primarily include the spring's material diameter, free length, free angle, spring diameter, total number of turns, length of torsion arm, bending angle of torsion arm, and so on. These are the fundamental spring testing items. discrepancies in size, especially with super-large springs, are likely to contribute to discrepancies in overall device performance.

Testing equipment: calipers, two-dimensional, three-dimensional, projector, etc.

5. Spring elasticity test

If the spring force value is clearly marked on the drawing, the matching spring force test must be performed. Typically, the elastic force tester can be used to detect the necessary elastic force; simply pay attention to the distance of pushing or stretching according to the drawing requirements and then check the relevant elastic force. This type of test is commonly used for slightly bigger springs, such as mechanical springs and engineering springs, whereas battery box springs or ultra-precise micro springs do not normally require it.

Testing equipment: elastic tester, tensile tester, etc.

6. Salt spray test of spring

The Salt spray test is also a popular test for spring items. Use varied hours of salt spray oil to prevent rust on the spring according to customer specifications, then take pictures and record the test results in 2/4/8 hours, and finally generate a test report.

If it fails the salt spray test, the spring must be treated with salt spray oil to meet the test criteria, preventing rust and deterioration during its service life and causing safety issues.

Testing equipment: salt spray tester.

7. Impedance test

Impedance levels are commonly specified for battery box springs and springs with conductive applications. The requisite impedance test must then be performed in accordance with the specifications of the customer's designs. If the test fails, the impedance value

Testing equipment: resistance tester.

The things listed above are the most common spring detecting methods and associated equipment. You are welcome to submit supplements and ideas if there are any deficiencies!is normally adjustable by adjusting the material, inner and outer diameter, wire diameter, length, plating, and so on.

Comments (0)